#compressive #strength of #concrete

B.S. 1881-1970

It shows the resistance of concrete against the force of weight. It is also one of the most important factors of concrete quality control.

Resistance varies with grade, for example:

Concrete 300 means the amount of concrete in 1 cubic meter is 300 kg.

300 grade concrete: It represents the amount of cement used in one cubic meter. That is 300 kilograms per cubic meter

Grade: The weight of cement in one cubic meter

Resistance: It expresses the tolerance value of the sample in terms of compressive strength. The amount of force that enters the concrete and breaks the concrete.

With the same grade of cement, we may have different resistances due to the difference in the type of granulation.

The amount of resistance varies according to the type of structure. For example, it is 200 in the foot of the concrete and 300 in the concrete column.

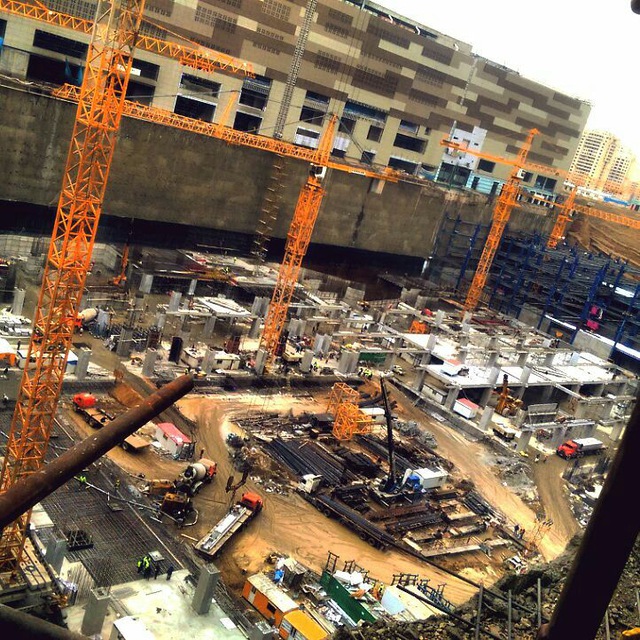

In construction projects, sampling of fresh concrete is done.

Sampling types: Sampling is done in two ways: cube and cylinder.

Dimensions of samples:

Cubic samples with dimensions:

Cylindrical samples:

The resistance of cubic samples in the standard is equal to 0.8 of the resistance of cylindrical samples.

The resistance of the cube sample is 0.8 = the resistance of the cylindrical sample

The standard considers the resistance of the sample based on the resistance of the cylindrical sample, and in the regulations, the resistance is considered based on the cylindrical sample.

Types of strength: concrete strength is expressed in the state of initial strength and ultimate strength.

The initial resistance is the same as the 7-day resistance determined for ordinary cements.

The ultimate strength, which is stated in most regulations, is the 28-day strength of concrete.

7-day resistance is approximately 0.75 of 28-day resistance.

Test preparations:

To perform this test, we first measure the weight of the sample using a scale and measure the length, width, and height using a caliper.

To get the length, we have to measure four points, then we average the four points to get the length, but for width and height, one measurement is enough.

Test sample dimensions:

Length: 15cm, width: 15.04cm, height: 15cm

Due to having 5 smooth and polished surfaces, cubic samples will not have any problems during testing in the machine, but cylindrical samples need to be cupped (improved) due to not having a smooth surface.

Cupping is done using cement with high resistance or with a machine.

Testing tools:

Sample, scale, ruler and jack

The jack of this experiment is known as the 200 ton jack.

200 tons is the maximum force that the jack can apply.

This jack consists of two jaws, the upper jaw is the fixed jaw and the lower jaw is the movable jaw.

Based on the type of sample (cubic or cylindrical), the standard specifies the amount of force that must be applied in 1 second.

For cubic samples, the amount of force applied in 1 second is 680.

The machine has two hands, black and red. When the force is applied, both hands start to move. When the concrete is broken and the machine is turned off, the black hand returns to its original state, and the red hand, which indicates the amount of force, remains fixed.

Test result:

The tested cubic sample started to crumble under a pressure equal to 30 tons.

By dividing this number by the surface, compressive resistance is obtained.

This post is written by Mehrad_tehrani